Liberty STEAM Charter School’s 3rd Annual Workforce Development Day

Liberty STEAM Charter School’s 3rd

Annual Workforce Development Day

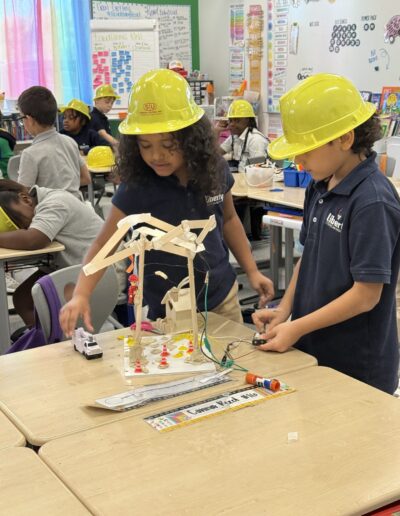

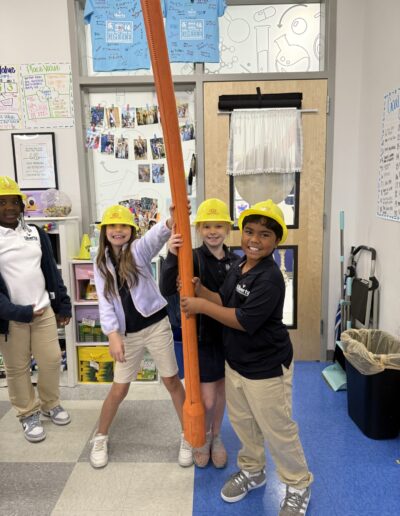

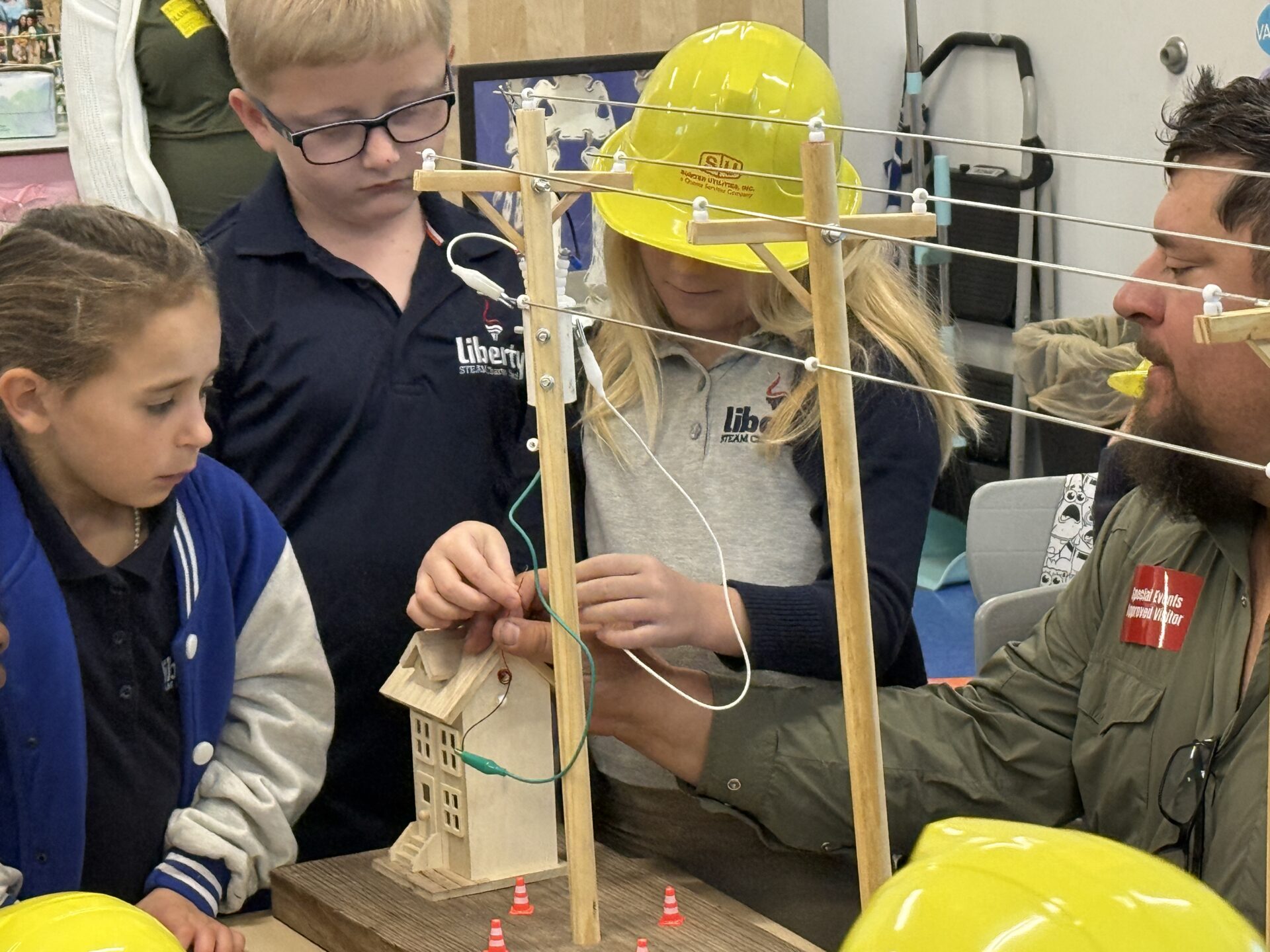

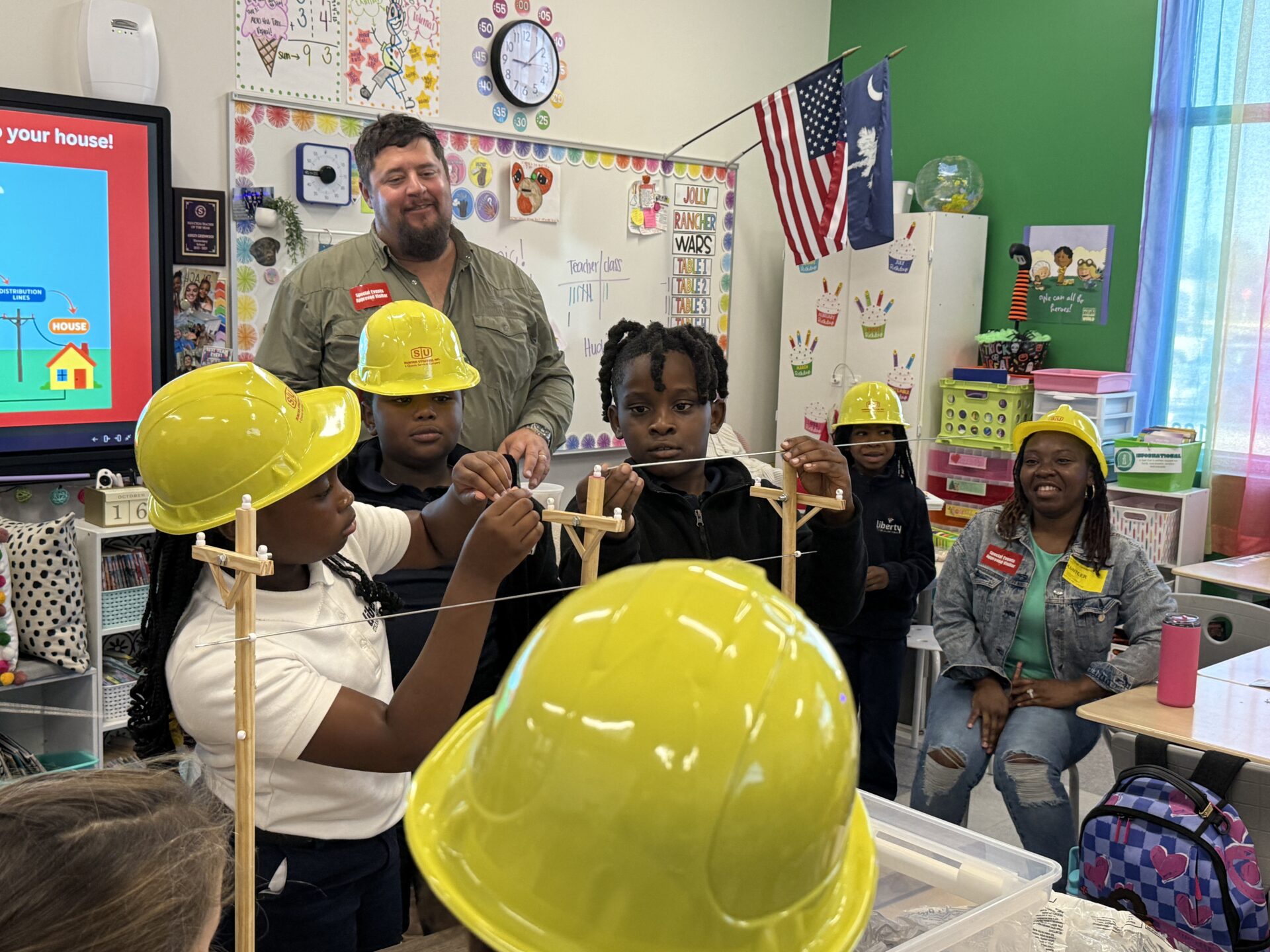

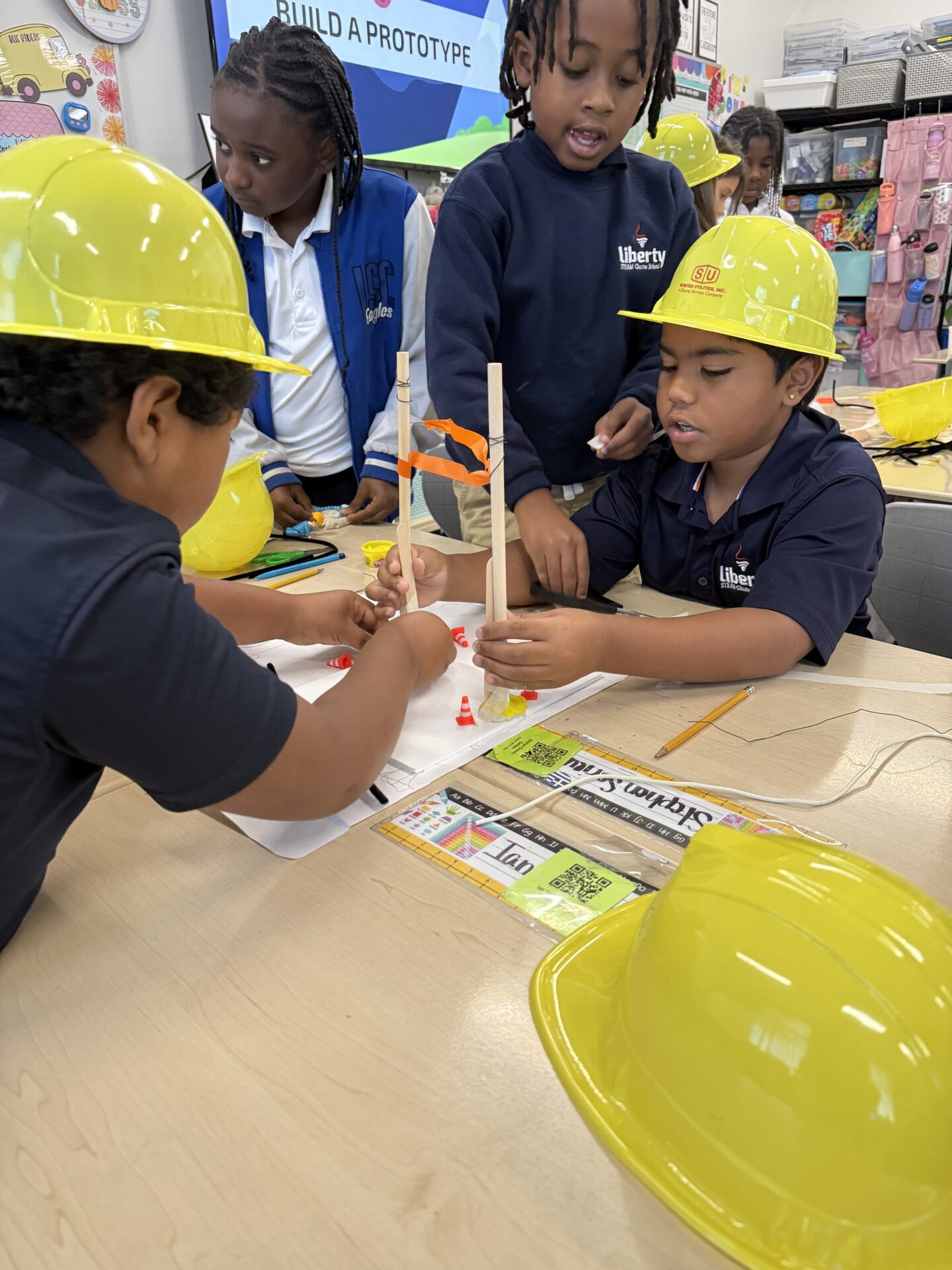

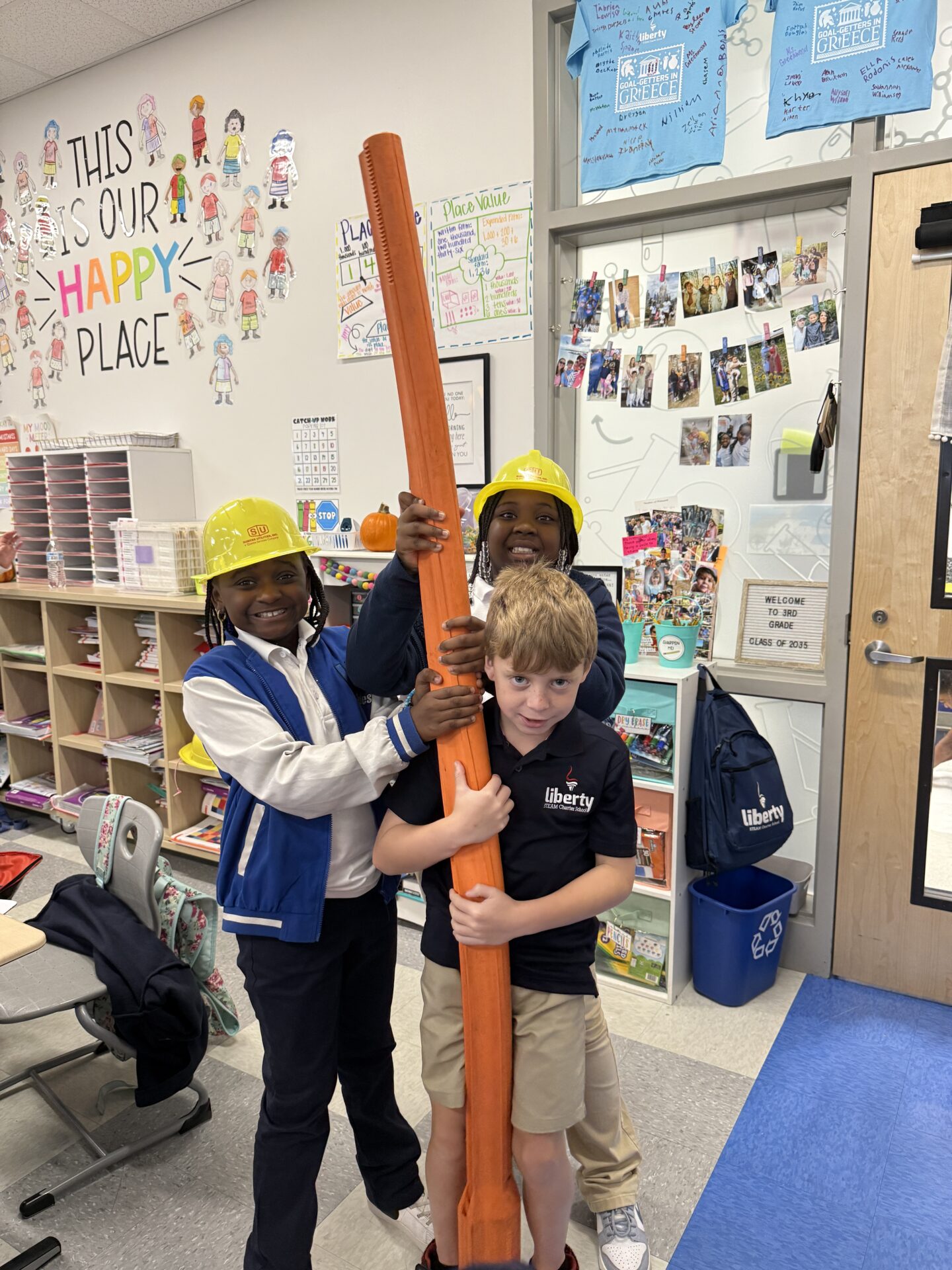

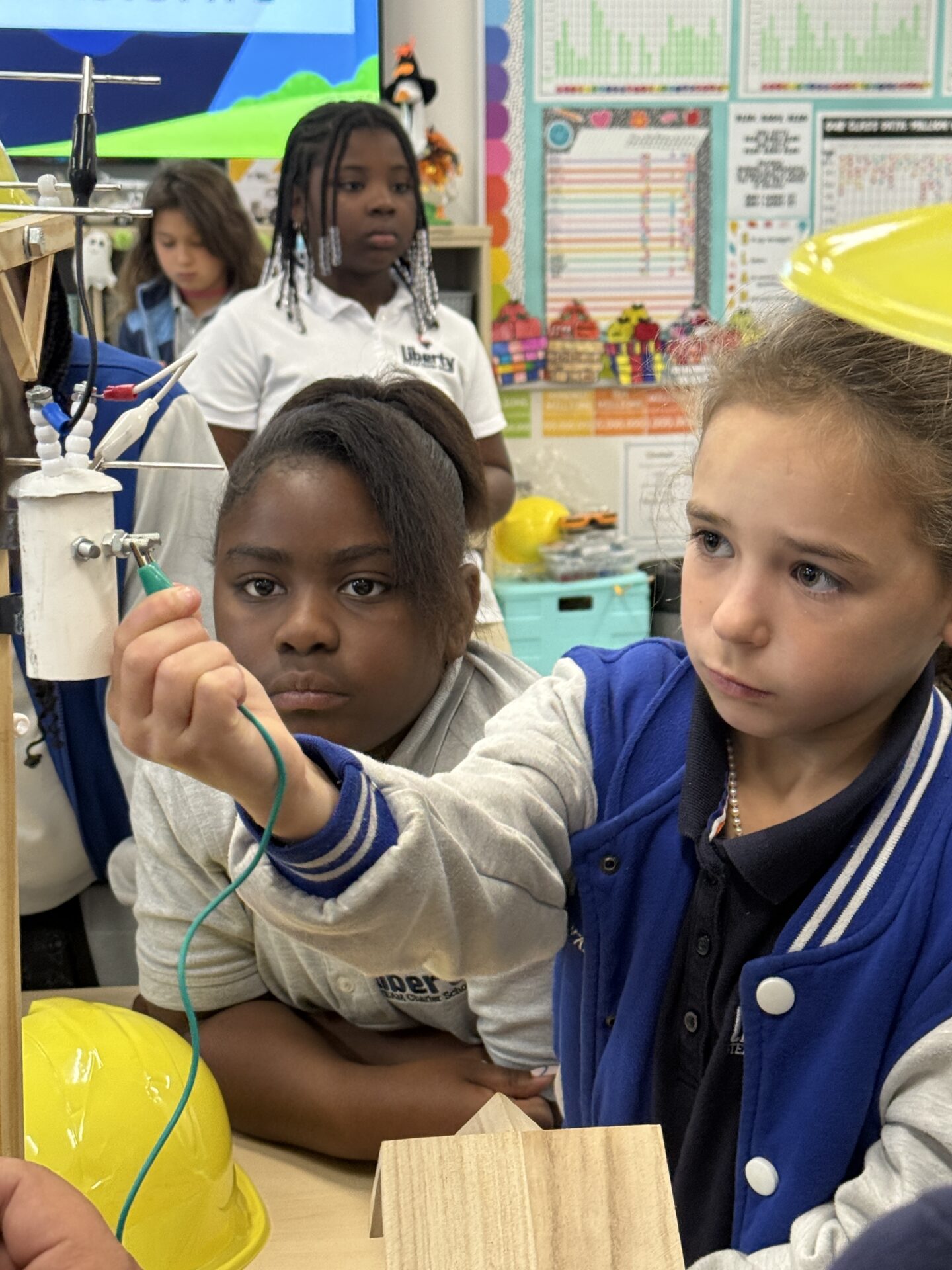

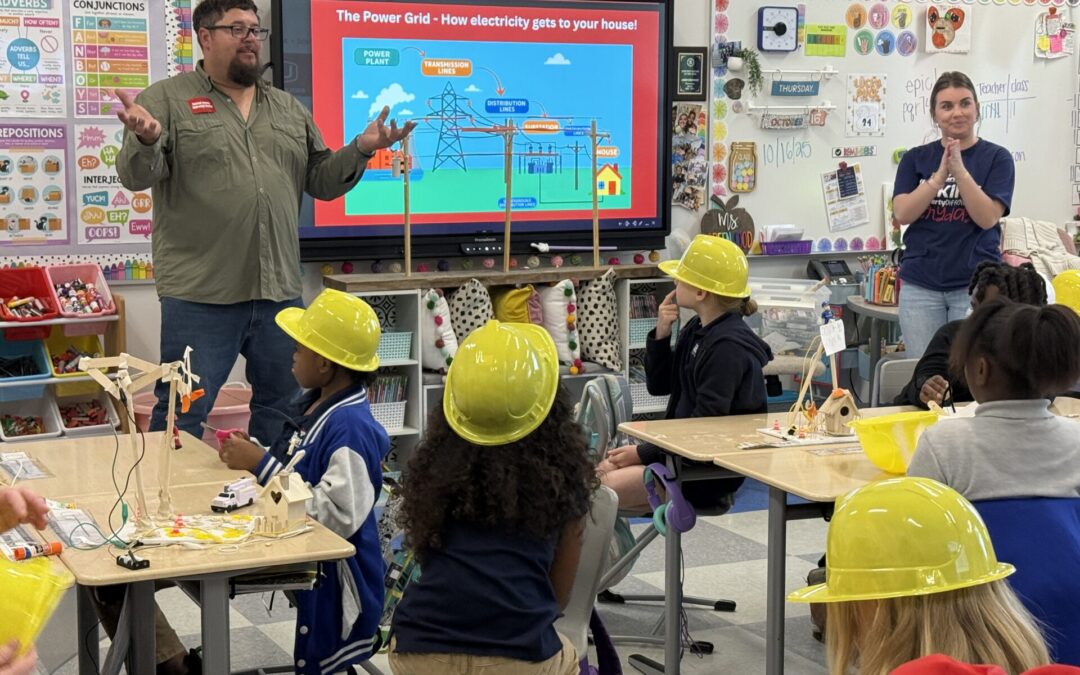

October 15, 2025 was PATH Expedition Project Day at Liberty STEAM Charter School — one of our favorite annual traditions! Each year, we partner with a third-grade class to bring hands-on learning to life. This year, we had the pleasure of working with Ms. Greenwood’s class, where Corey Blackmon led the students through an exciting demonstration: building an overhead power line to light up a house.

The students rolled up their sleeves to help construct the main model, then teamed up to create their own smaller versions. Throughout the activity, safety was the top priority. Corey emphasized the importance of rubber hoses and blankets for insulation and ensuring every project included a clearly marked “drop zone” to protect against potential falling hazards.

Next month, each class will showcase their projects to a panel of local dignitaries — and one winning design will be crowned this year’s PATH Expedition Champion!

We’re excited to continue partnering with Ms. Greenwood’s class throughout the school year to share more about our trade, helping students understand how power is delivered to their homes and inspiring the next generation of skilled tradespeople.